Polyphosphazene

| "It is felt that the polyphosphazenes may be the most important class of inorganic polymers since the commercialization of the silicones." |

|

- US Army Materials Research |

|

|

|

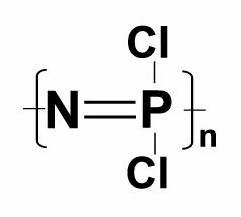

Polyphosphazene 'backbone' Polymer |

The phosphazene polymers constitute a family of greatly diverse performance materials. These polymers possess a 'backbone' of alternating nitrogen and phosphorous atoms. To a basic 'backbone' polymer, a variety of substituents can be added that control the physical properties of the final product. There are over 700 known phosphazene derivatives, many of which have been custom-configured for end applications or value added characteristics. Although the substituents are the main influence on the polymer's physical properties, phosphazene polymers can provide the following characteristics: Bio-compatibility, Flexibility, High Dipole Moment, Broad Range of Tg (glass transition temperature), Chemical Inertness, Mechanical Strength, Solvent Permeability or Impermeability, Elastomeric Properties, and Flame-Retardancy. Because of the endless number of permutations of substituents that can be attached to the basic 'backbone' polymer, polyphosphazenes can be customized to suit any client's performance-polymer needs.

,technically, Incorporated and Polyphosphazene

,technically, Incorporated has manufactured polyphosphazene derivatives since 1994. The firm provides material for government, military, and industrial applications and is known not only for providing the highest quality, customizable material for research, but also for its ability to produce manufacturing quantities. ,technically,'s team of Polyphosphazene scientists and engineers is made up of the leading researchers, innovators, and manufacturing personnel in the industry and is the recognized leader in polyphosphazene manufacturing.

,technically, combines its abilities to synthesize organic polymers with its expertise in experimental design to come up with scalable synthetic routes to phosphazene polymers. Our scientists and engineers are experts in process optimization and scale-up, and our modular pilot plant facility lends itself to quick commercialization. Thus, ,technically, can bring research-scale to commercial reality.

Although polyphosphazenes can be customized for virtually any application, most activity can be grouped into four segments: Fuel Cell , Medical, High Performance, and Membrane.

Fuel Cell: A fuel cell is a device that produces electricity by efficient electrochemical conversion of fuel. Polyphosphazene is currently the highest performing membrane material for Methanol based Proton-Exchange Membrane (PEM) Fuel Cells. This fuel cell type is ideal for miniature power supply and is a leading candidate for automotive applications. Specially-fabricated polyphosphazene membranes possess high proton conductivity, slow methanol transport, and stability (thermal, mechanical, and chemical). They out-perform most other membrane materials in methanol environments and have demonstrated minimal methanol crossover, better thermal performance in high-temperature environments, and minimal chemical and mechanical degradation.

Medical: Polyphosphazenes make ideal medical polymers because of their biocompatibility, capability for intricate customization, high affinity for water, and the ability to accept grafts of influencing substituents. Medical applications include: Drug Delivery, Biological Membranes, Coatings, and polymeric medical devices and components such as prosthetics and implants. Drug delivery systems utilize polyphosphazene's ability to accept grafts of active components to create a 'carrier-molecule' for the pharmaceutical. In addition, a substituent capable of influencing the behavior of the chain (i.e.: accelerating hydrolysis), can be added, enabling the rate of release to be a function of the polymer characteristics and substituent ratios. Phosphazenes are also used as surface coatings and composite materials. Derivatives have been synthesized to be inert in biological media and are known to function well subcutaneously.

High Performance: Polyphosphazenes are used as flame retardants, additives, performance polymers, and in specialty applications. The exceptional performance of polyphosphazene derivatives under extreme temperature conditions, their inertness to chemical environments, and their non-flammability, make them premiere materials for applications in hostile landscapes. Polyphosphazene derivatives have been synthesized that exhibit a low Tg (-65oC) with a thermal operating temperature range from -90 to 200oC. Their excellent combustion behavior such as low smoke emission, no corrosiveness, low toxicity of gases, and their ability to withstand a diversity of hostile chemical environments make them premiere materials for uses in fluoroelastomeric seals, gaskets, O-rings, and in insulating foams. Other products include specialty rubbers, flame resistant materials, polymer conductors, lubricants, liquid crystal polymers, catalysis, paints, adhesives, photocuring polymers, self-stabilized polymers, and additives.

Membrane: Polyphosphazenes are being used to make membranes more thermally, mechanically, and chemically stable, as well as to enhance selectivity and overall performance. They are mainly used in electrodialysis, microfiltration, ultrafiltration, and reverse osmosis applications. They can be engineered as membranes per se or in hollow tube and depth media. Phosphazene membranes have shown immense potential in water purification, fuel-gas technologies, air enrichment, sour gas purification, and in the separation of mixtures of alcohols and various organic compounds and ions.

,technically, Incorporate - Polyphosphazene Services

,technically, Incorporated offers a complete package of services for polyphosphazenes that address any need at any phase of product evolution. We offer our clients full customization and technical support, as well as provide an output range that is capable of servicing both R&D and Commercial projects.

We provide:

- Gram to Commercial Quantities

- Technical Support and Consulting (polymer choices, structure-performance assistance, uses, handling, ...)

- Full-Customization (derivatives, MW, purity, ...)

- Access to Value-Added Supply Chains for main applications

- Linear Polymer Backbone: Dichloro-phosphazene backbone polymer ready for customization

- Fluoroelastomer: For high performance applications

- Fuel Cell Membranes

- Any Other Customized Derivatives

All products are of the highest quality and purity.

Contact us for more details.